Description

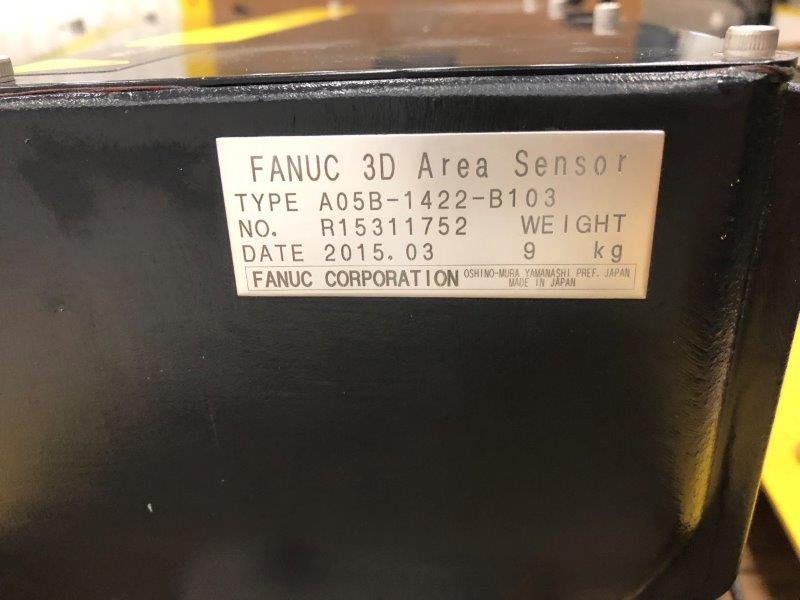

MANUFACTURER INFORMATION

FANUC 3D Area Sensor – Visual intelligence

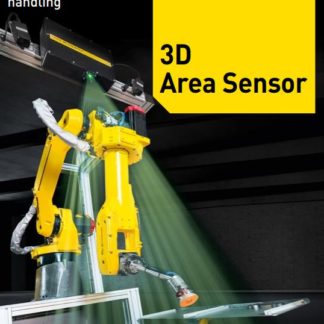

Advanced bin picking and general material handling

Productive automated handling for more efficiency and flexibility

Robots equipped with FANUC 3D Area Sensors represent a great way of increasing your productivity and reducing your costs on a vast range of general material handling applications. Capable of locating parts three dimensionally, they add flexibility and reliability to operations traditionally completed by humans or otherwise requiring sophisticated and expensive dedicated machinery. No matter whether your process involves loose, mixed, irregular parts, sacks or bags, equipping a robot with a 3D Area Sensor provides an efficient solution that can be quickly adapted to handle different products in accordance with your order books. How it works Completely integrated into the robot controller, FANUC‘s high-speed 3D Area Sensor uses structured light projection to create 3D maps. Using these maps, the system looks for parts. The part manager then does an evaluation and decides which part to pick. Taking reaching distance and collision avoidance into account, it then chooses the fastest picking option. If the part manager decides a pick has been unsuccessful or a part queue does not contain a part to pick, another image is taken and the process starts again using the new results.

Additional facts

- out of the box functionality, including all the tools and features needed (plug and play)

- intelligent part management ensures picking is evenly distributed across the bin

- part detection takes place while the robot is moving and does not interrupt the workflow

- familiar iRVision interface makes it easier to understand and use

- standard TP programming skills are sufficient to create and implement an application

- full iRVision functionality plus special locator tools for the 3D Area Sensor

- bin picking is fully supported by FANUC Roboguide simulation software

- no additional light required

- all components – hardware and software – 100% FANUC