Description

Other manufacturer options include seals of Nitrile (NBR) or (EPDM).

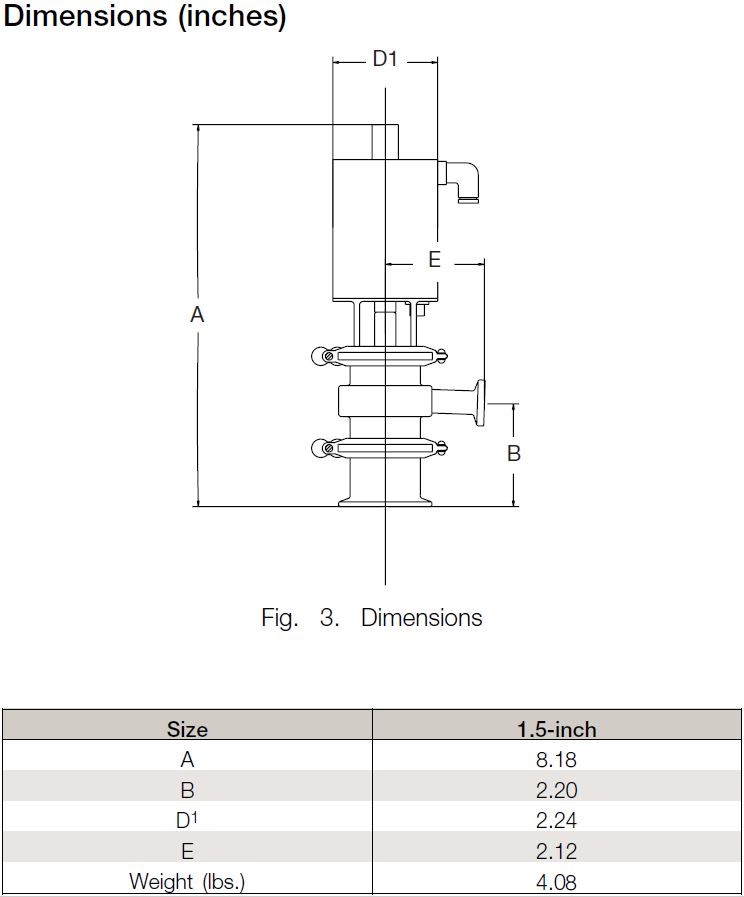

Connections:

Compressed Air: 1/4″ poly tubing (0.25in)

Vent: 1/2″ Tri-Clamp (0.5in)

Process/CIP: 1-1/2″ Tri-Clamp (1.5in)

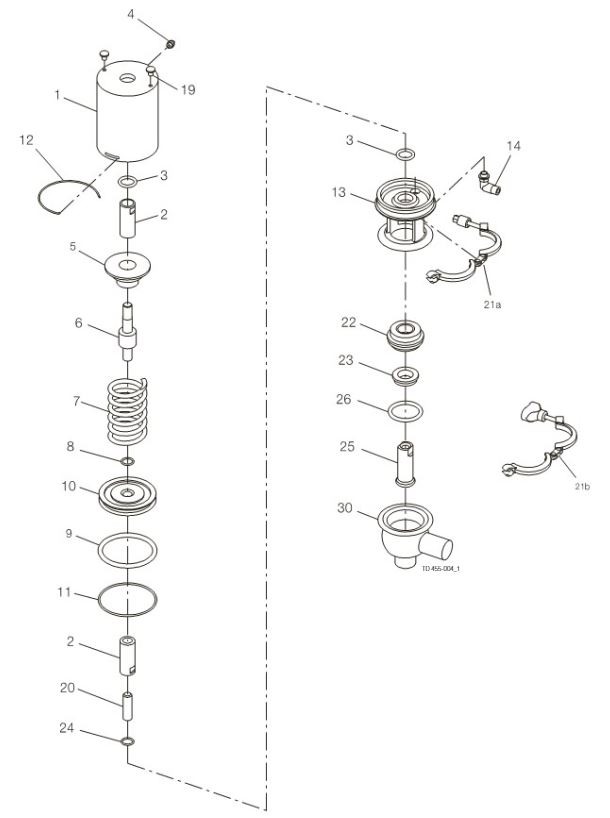

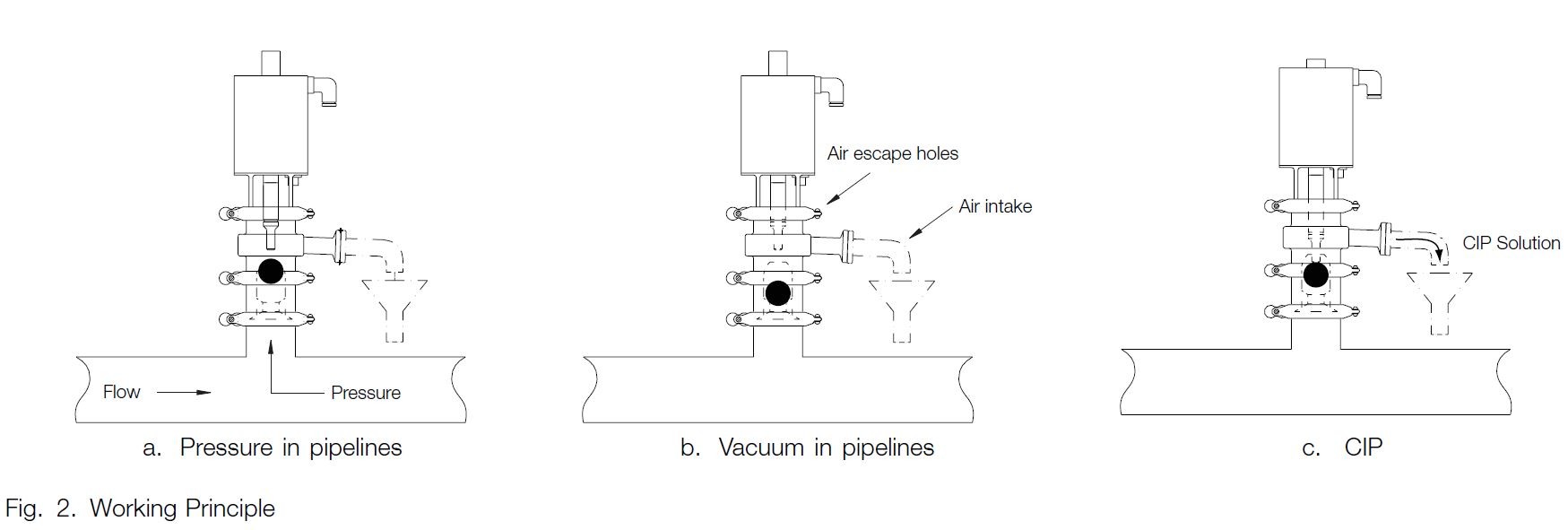

Working principle

The working principle is similar to that of a ball check valve. When pipelines are pressurized during process or CIP, the internal ball is

forced upward against its seat, closing the vent port (see fig. 2a). When pipeline pressure drops, the ball is drawn down, allowing air to

enter the vent, thereby preventing vacuum in the system (see fig. 2b). During CIP, a pneumatic actuator is used (pulsed) to force the ball off

the upper seat, allowing cleaning of the seat and the internals of the vacuum breaker valve. The CIP fluid discharged during the actuator

pulse is ushered to drain via the vent port (see fig. 2c).

Technical data

Valve:

Maximum product pressure . . . . . . . .145 PSI

Minimum product pressure . . . . . . . . .Full vacuum.

Temperature range . . . . . . . . . . . . . .14° F to 225° F

Actuator:

Maximum air pressure . . . . . . . . . . . .101.5 PSI

Minimum air pressure . . . . . . . . . . . .73 PSI

Materials

Valve/Actuator:

Product wetted steel parts: . . . . . . . . .AISI 316L

Product wetted seals . . . . . . . . . . . .FPM

Ball . . . . . . . . . . . . . . . . . . . . . . . .Polypropylene HD

Finish: . . . . . . . . . . . . . . . . . . . . . .≤32 RA

Actuator:

Seals . . . . . . . . . . . . . . . . . . . . . . .NBR

Finish . . . . . . . . . . . . . . . . . . . . . . .Semibright

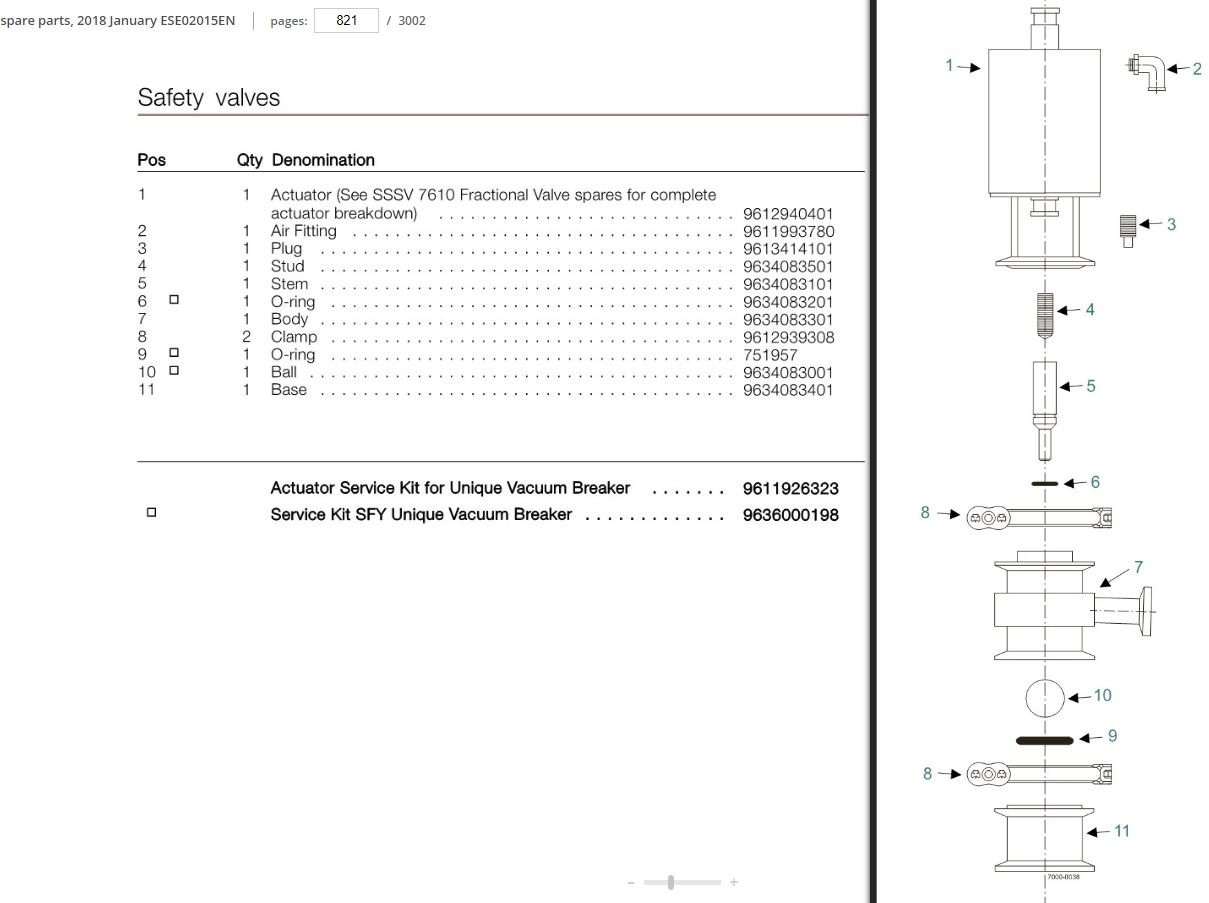

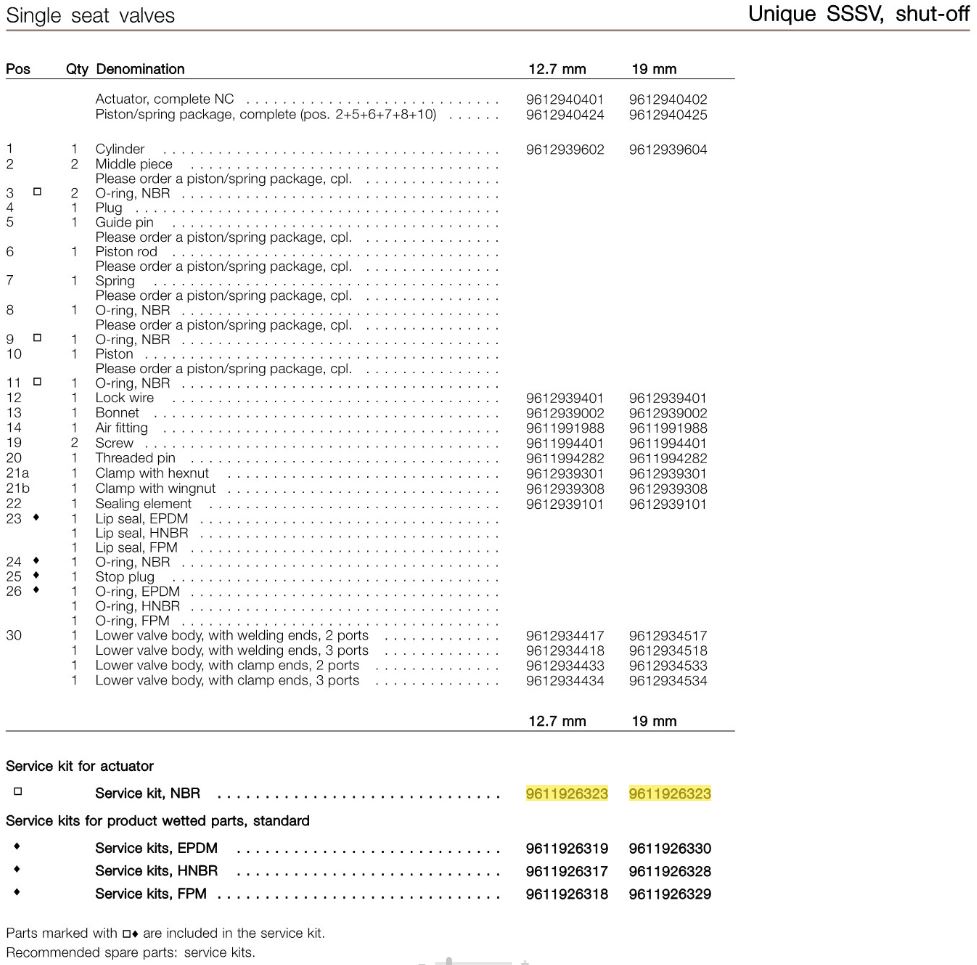

Spare Parts Breakdown