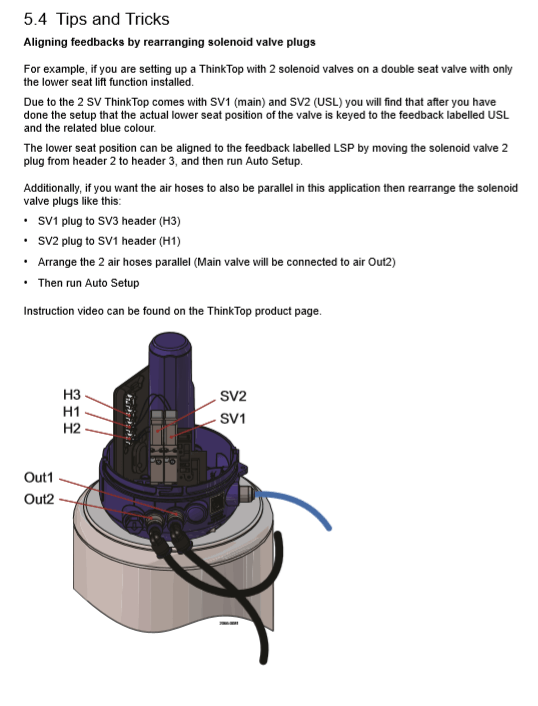

Description

Introduction

ThinkTop V50 and V70 take valve control to a new level and use all features available on the Alfa Laval diaphragm, butterfly, single-seat and mixproof valves. While helping to increase production performance and secure trace-ability, ThinkTop V50 and V70 provide real-time information on valve operating status 24/7. Both ThinkTop V50 and V70 are interchangeable with prior ThinkTop versions, and the appropriate variant is selected based on the number of solenoid valves. With only one sensor target and one adapter, ThinkTop V50 and V70 fit onto all actuators equipped with mushrooms. ThinkTop V50 and V70 come fitted with features such as Auto Setup, Live Setup and Flex Setup that streamline the setup process, making it quick and easy. Auto Setup and Live Setup recognize the valve based on its DNA profile and can complete the valve setup without any manual interaction. The burst seat clean function is available on ThinkTop V70. This function controls the optimum open position of the valve, making it possible to achieve up to 90% CIP liquid savings for each seat lift.

Application

ThinkTop V50 and V70 are designed for use in the dairy, food, beverage, and bio-pharma industries.

Benefits

• Automatic setup

• Automatic valve recognition

• Automatic selection of tolerance band

• Fast Auto, Live and Flex Setup

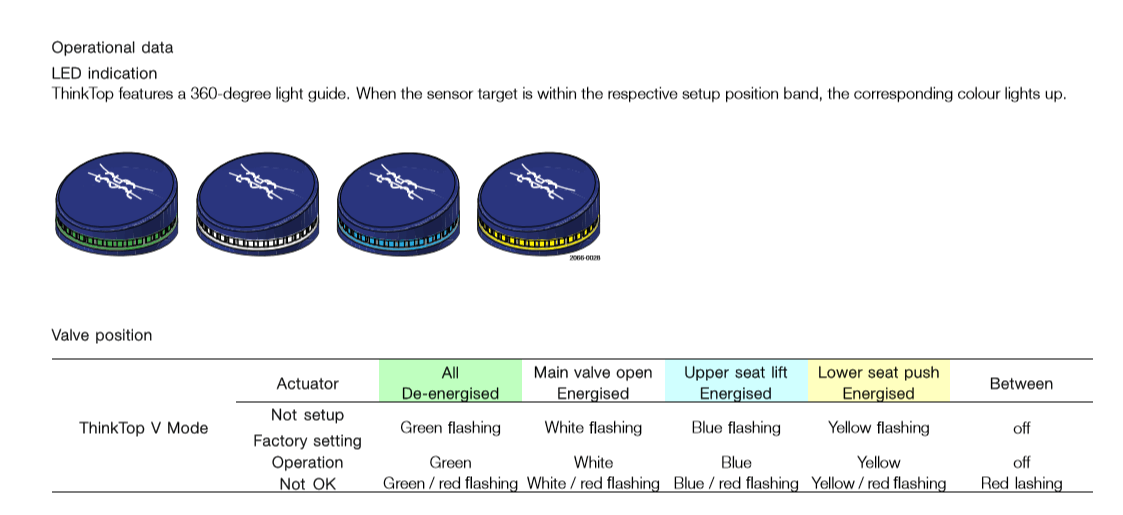

• 360-degree LED indication

• Burst seat clean

• Exchangeable (threaded) air-fittings

• Interchangeable with ThinkTop classics

Working principles

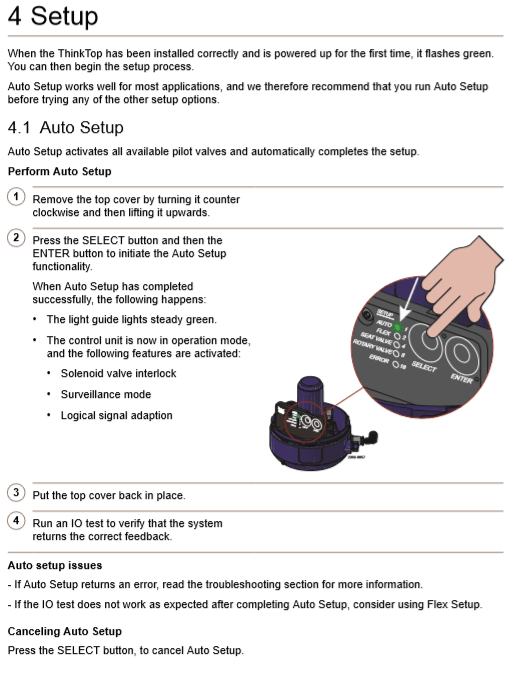

The control unit offers a single sensor solution for diaphragm, butterfly, single-seat and mixproof valves and it can be fitted with up to three solenoid valves. ThinkTop converts the electrical PLC output signals into mechanical energy to energize, or de-energize, the air-operated valve, using the physical sensor target mounted on the valve stem. Installation with Auto Setup or Live Setup is intuitive and fast. To initiate Auto Setup, simply press the “SELECT” button and then the “ENTER” button to begin the setup sequence. The process is completed in accordance with the number of solenoid valves fitted to the control unit. Alternatively, the ThinkTop can be set up, without dismantling the control head, using the built-in Live Setup feature for remote-configuration.