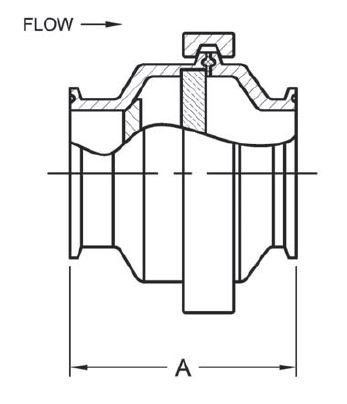

Description

PART# | SIZE | A DIM. (in) – OAL | Cracking Pressure (psi) | Flow Coefficient (CV)

KCA00501 – 45MP-.50-CD-316 | 1/2 | 2.7″ OAL | 1.31 PSI | 5 CV

KCA00751 – 45MP-.75-CD-316 | 3/4 | 2.7″ OAL | 3.34 PSI | 4 CV

KCA01001 – 45MP-1-CD-316 | 1 | 3.29″ OAL | 10.88 PSI | 20 CV

KCA01501 – 45MP-1.5-CD-316 | 1-1/2″ OAL | 3.36 | 18.85 PSI |20 CV

KCA02001 – 45MP-2-CD-316 | 2 | 3.36″ OAL | 6.38 PSI | 40 CV

KCA02501 – 45MP-2.5-CD-316 | 2-1/2″ OAL | 3.36 PSI | 60 CV

KCA03001 – 45MP-3-CD-316 | 3 | 3.36″ OAL | 4.8 PSI | 100 CV

KCA04001 – 45MP-4-CD-316 | 4 | 4.03″ OAL | 6.09 PSI | 210 CV

Max. Temperature – 248°F

Max. Pressure – 145 psi

NOTE: DRAWING, PART NUMBERS, AND DIMENSIONS SHOWN ARE FOR

CLAMP END STYLE CHECK VALVE.

CALL FOR DETAILS ON OTHER CONFIGURATIONS.